| Product name | 304 Stainless Steel Woven Mesh |

| Material | SUS 304 (18% Chromium, 8% Nickel, ≤0.08% Carbon) |

| Mesh Size | 1 Mesh – 635 Mesh (standard), ultra-fine meshes (<1µm) available |

| Wire Diameter | 0.025mm – 6.0mm (customizable) |

| Free simple | Sample is available |

| Packaging | Moisture-proof paper + bubble wrap + wooden box |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

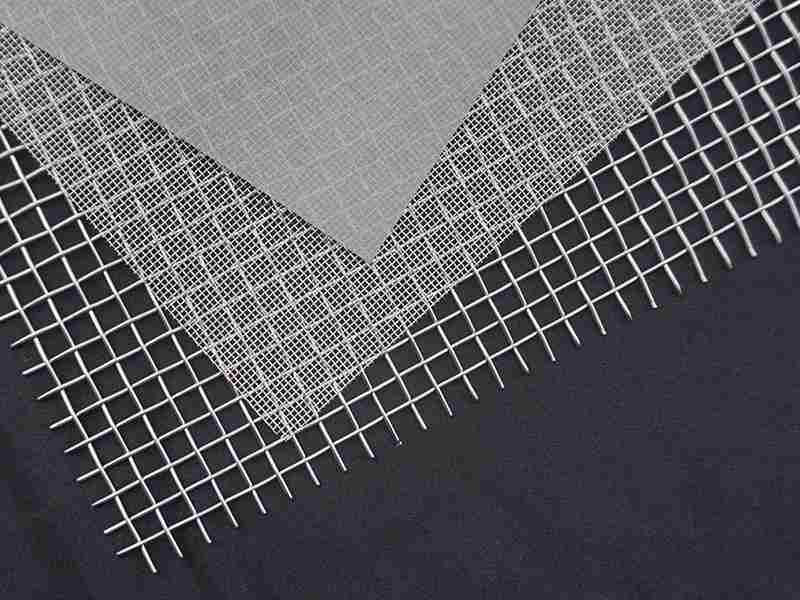

304 stainless steel woven mesh is a high-quality metal woven product of our company, which is made of selected 304 stainless steel wires through advanced mechanical weaving technology. With its excellent comprehensive performance, 304 stainless steel has become an ideal material for woven mesh, endowing the product with a series of excellent characteristics and playing a key role in many industries.

Material Characteristics

- Strong Corrosion Resistance: 304 stainless steel is rich in alloying elements such as chromium (Cr) and nickel (Ni). The chromium content is more than 18%, which can form a dense and strong oxide film on the surface of the woven mesh. This oxide film, like a strong shield, effectively blocks the erosion of various corrosive media such as acids, alkalis, salts, and water vapor. Even in harsh chemical environments, the woven mesh can remain stable for a long time without being corroded and damaged, which greatly prolongs the service life of the product. It is very suitable for use in environments with strong corrosiveness such as chemical industry and marine fields.

- Excellent High/Low Temperature Resistance: In high-temperature environments, when the temperature is between 300°C and 800°C (depending on the actual working conditions and slight differences in materials), 304 stainless steel woven mesh can maintain good structural stability and mechanical properties, and will not deform, soften or have a significant decrease in strength due to high temperature. In low-temperature environments, it is not easy to embrittle and still has reliable toughness and strength, which can meet the needs of use under different temperature conditions such as high-temperature industrial furnace gas filtration and low-temperature liquid storage filtration.

- High Strength and Good Wear Resistance: 304 stainless steel itself has high strength. After being made into steel wires and woven into a mesh, the structure becomes more compact. This compact structure endows the woven mesh with excellent tensile, compressive and wear-resistant properties. When facing the impact of high-pressure and high-velocity fluids and the friction of solid particles, the woven mesh can effectively resist, reduce wear and damage, ensure long-term stable operation, and reduce the frequency of equipment maintenance and replacement.

Structural Characteristics

- Flexible Customization: Our company is well aware of the diverse needs of different customers in different application scenarios. Therefore, the mesh shape, aperture size and wire diameter of 304 stainless steel woven mesh can be accurately adjusted according to the actual requirements of customers. The mesh shape can be common square, rectangle, or special shapes such as rhombus; the aperture size ranges from micron-level ultra-fine apertures to centimeter-level larger apertures; the wire diameter can also be flexibly selected. This high degree of customization capability enables the product to perfectly adapt to various complex and special application scenarios.

- High Permeability and Filtration Precision: Through precise weaving technology, the meshes of 304 stainless steel woven mesh are uniform. The uniform meshes ensure stable and precise filtration performance. In the screening and filtration process, it can efficiently separate particles and impurities of different sizes. In industries such as food and medicine that have extremely high requirements for particle classification accuracy, the woven mesh can accurately screen out products that meet the standards, ensuring product quality and safety. At the same time, the uniform meshes also ensure good permeability, allowing fluids to pass through smoothly and reducing pressure loss.

- Excellent Structural Stability: The weaving process endows 304 stainless steel woven mesh with good structural stability. The meshes are intertwined and closely connected, forming a stable whole that is not easy to deform. Even under long-term exposure to large pressure, tension, or mechanical impact and vibration, it can still maintain its original shape and structural integrity, ensuring that the filtration and screening effects are not affected, and providing a solid guarantee for the stable operation of equipment.

- Easy to Clean and Maintain: The surface of 304 stainless steel woven mesh is smooth and flat, which makes it not easy to attach dirt and impurities. During daily use, if there are pollutants on the surface of the woven mesh, cleaning and maintenance work is very simple. It can be directly rinsed with water, using the impact force of the water flow to take away surface impurities; it can also be cleaned by wiping; for some stubborn stains, appropriate chemical cleaning agents can be used for cleaning. The simple and convenient cleaning and maintenance methods greatly reduce the use cost and maintenance workload.

Applications

1. Filtration & Separation

- Chemical Processing – Filters acids, alkalis, and solvents.

- Oil & Gas – Sand control screens, catalyst retention.

- Food & Beverage – FDA-compliant sieving for powders/liquids.

2. Architectural & Decorative

- Building Facades – UV-resistant, weatherproof cladding.

- Interior Design – Balustrades, room dividers, artistic installations.

3. Industrial & Mechanical

- Safety Guards – Machine protection with high impact resistance.

- Heat Resistance – Furnace trays, exhaust systems.

4. Aerospace & Automotive

- EMI Shielding – Protects sensitive components.

- Vibration Damping – Reinforced mesh for engine parts.