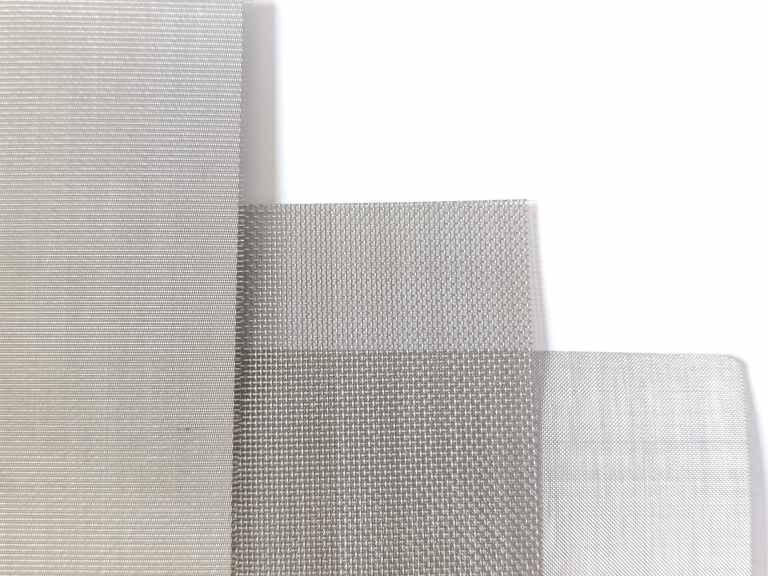

| Product name | 430 Stainless Steel Wire Mesh |

| Material | AISI 430 (16-18% Cr, ≤0.12% C, ≤1.0% Mn, ≤1.0% Si) |

| Mesh Size | 2 Mesh – 400 Mesh (standard) |

| Wire Diameter | 0.05mm – 3.0mm (customizable) |

| Free simple | Sample is available |

| Packaging | Moisture-proof paper + bubble wrap + wooden box |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

430 stainless steel wire mesh is a cost-effective and reliable metal mesh product manufactured by our company, using high-quality 430 ferritic stainless steel wires. As a ferritic stainless steel, 430 is characterized by its chromium-rich composition (without nickel), offering a balance of corrosion resistance, formability, and affordability. It is an ideal choice for applications where moderate corrosion resistance is required, and cost efficiency is a key consideration, making it widely used in various industrial and commercial fields.

Material Characteristics

- Moderate Corrosion Resistance: 430 stainless steel contains approximately 16-18% chromium, which forms a protective oxide layer on the surface of the woven mesh. This layer provides resistance to corrosion in mild environments, such as atmospheric conditions, fresh water, and some non-aggressive chemicals. While it is not as resistant to harsh corrosive media (like high chloride solutions or strong acids) as austenitic stainless steels (e.g., 304 or 316), it performs well in dry or slightly humid environments, making it suitable for many general-purpose applications.

- Good Mechanical Properties: 430 stainless steel wire mesh exhibits decent tensile strength and ductility, allowing for easy fabrication, cutting, and forming. It can be bent, welded (with appropriate techniques), and shaped into various forms without significant loss of structural integrity, providing flexibility in installation and application.

- Magnetic Properties: Unlike austenitic stainless steels, 430 is magnetic, which makes it suitable for applications where magnetic properties are required, such as in magnetic separation systems or components that need to interact with magnetic fields.

- Heat Resistance: It can withstand moderate temperatures, up to around 600°C in continuous use, making it suitable for applications involving low to medium heat, such as in oven racks, heat shields for non-critical components, and general-purpose high-temperature screening.

Structural Characteristics

- Uniform and Stable Mesh: Our 430 stainless steel wire mesh is produced using precise weaving techniques, ensuring uniform mesh size, consistent opening area, and reliable performance in screening, filtering, and separation tasks. The interwoven wires form a stable structure that resists deformation under normal mechanical stress, ensuring long-term functionality.

- Cost-Effective Design: The use of 430 stainless steel, which lacks nickel, makes the woven mesh more affordable compared to nickel-containing stainless steels. This cost advantage does not compromise basic performance, making it a practical choice for budget-conscious applications that do not require extreme corrosion resistance.

- Smooth Surface and Easy Maintenance: The surface of 430 stainless steel wire mesh is smooth, reducing the adhesion of dust, dirt, and light contaminants. It can be easily cleaned with water, mild detergents, or simple wiping, ensuring hassle-free maintenance in everyday use.

- Customizable Specifications: To meet diverse application needs, we offer a range of customization options for 430 stainless steel wire mesh. This includes varying mesh counts (from coarse meshes for heavy-duty screening to finer meshes for light filtration), wire diameters, mesh shapes (square, rectangular), and sheet sizes. Our team works closely with customers to deliver tailored solutions that fit their specific requirements.

Applications

1. Industrial Filtration

- Chemical Processing – Nitric acid filtration systems

- Water Treatment – Screen filters for non-chlorinated water

- Oil Filtration – Lubricant and fuel filters

2. Automotive Components

- Exhaust Systems – Heat shields and muffler components

- Fuel Filters – High-flow filtration elements

- EMI Shielding – Electromagnetic interference protection

3. Food Processing

- Grain Sorting Screens – Dry material separation

- Baking Equipment – Conveyor belts and oven components

- Food Display Racks – Hygienic surface properties

4. Consumer Products

- Appliance Grilles – Refrigerator and oven components

- Security Screens – Window and door protection

- Industrial Dryers – Mesh belts for drying systems