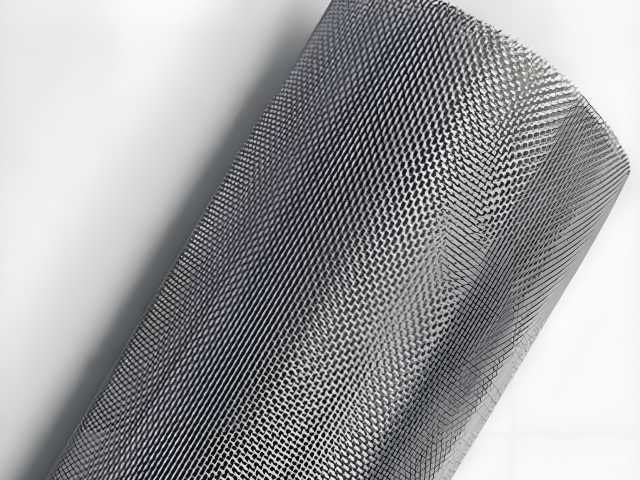

| Product name | 310S Stainless Steel Wire Mesh |

| Material | AISI 310S (24-26% Cr, 19-22% Ni, ≤0.08% C, ≤2.0% Mn) |

| Mesh Size | 1 Mesh – 300 Mesh (standard) |

| Wire Diameter | 0.05mm – 5.0mm (customizable) |

| Free simple | Sample is available |

| Packaging | Moisture-proof paper + bubble wrap + wooden box |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

310S stainless steel wire mesh is a high-performance metal mesh product expertly manufactured by our company, utilizing top-grade 310S austenitic stainless steel wires. As a heat-resistant stainless steel, 310S is specifically formulated to excel in high-temperature environments, thanks to its high chromium (Cr) and nickel (Ni) content. This unique composition grants it exceptional oxidation resistance and mechanical stability at elevated temperatures, making it the go-to choice for industrial applications where extreme heat is a constant challenge.

Material Characteristics

- Exceptional High-Temperature Resistance: 310S stainless steel contains approximately 25-26% chromium and 19-22% nickel, which form a dense chromium oxide film on the surface. This film acts as a powerful barrier against oxidation, allowing the woven mesh to withstand continuous operating temperatures up to 1000°C and short-term exposure to temperatures as high as 1150°C. Even under prolonged heat exposure, it resists scaling, deformation, and loss of strength, ensuring reliable performance in high-heat settings.

- Good Corrosion Resistance: While primarily designed for high-temperature applications, 310S stainless steel also offers decent corrosion resistance in moderate environments. It can resist corrosion from dry gases, mild acids, and organic compounds, making it suitable for use in settings where both heat and moderate chemical exposure are present.

- High Strength and Ductility: 310S stainless steel wire mesh maintains good tensile strength and ductility at both room and high temperatures. This combination allows it to withstand mechanical stress and thermal expansion/contraction without cracking or breaking, ensuring structural integrity in dynamic high-heat environments.

- Excellent Weldability and Formability: The material exhibits good weldability, enabling easy fabrication and integration into complex high-temperature systems. It can be woven into various mesh patterns and shapes while retaining its heat-resistant properties, offering flexibility in design and application.

Structural Characteristics

- Uniform Mesh Construction: Our 310S stainless steel wire mesh is produced using precision weaving techniques, ensuring consistent mesh size, uniform opening distribution, and reliable filtration/screening performance. The tight interlacing of wires creates a stable structure that maintains its shape even under thermal cycling and mechanical stress.

- Thermal Stability: The woven mesh is engineered to resist thermal distortion, making it capable of withstanding rapid temperature changes without warping or losing its structural integrity. This thermal stability is crucial for applications involving fluctuating high temperatures, such as in furnaces and kilns.

- Durable Surface: The surface of 310S stainless steel wire mesh is smooth yet robust, withstanding abrasion and wear from high-velocity gases, particles, or mechanical contact. It is also easy to clean, as its high-temperature resistance allows for cleaning methods involving heat or chemical treatments suitable for high-heat equipment.

- Customizable Specifications: To meet diverse industrial needs, we offer extensive customization options for 310S stainless steel wire mesh. This includes varying mesh counts (from coarse meshes for heavy-duty screening to finer meshes for gas filtration), wire diameters, mesh shapes (square, rectangular), and sheet sizes. Our team works closely with customers to tailor the mesh to their specific high-temperature application requirements.

Applications

1. High-Temperature Industrial Furnaces

- Heat Treatment Furnace Components – Basket meshes, conveyor belts

- Ceramic Kiln Furniture – Sintering trays and support grids

- Annealing Furnace Parts – Internal screens and protective layers

2. Petrochemical Processing

- Reformer Furnace Components – Catalyst support grids

- Ethylene Cracker Parts – Radiation shields and tube supports

- Hydrogen Plant Equipment – High-temp filtration elements

3. Power Generation

- Boiler Components – Burner screens and combustion chambers

- Waste Incineration – Grate systems and ash filters

- Gas Turbines – Heat shields and exhaust components

4. Glass Manufacturing

- Glass Furnace Parts – Molten glass contact components

- Lehr Conveyor Belts – For glass annealing processes