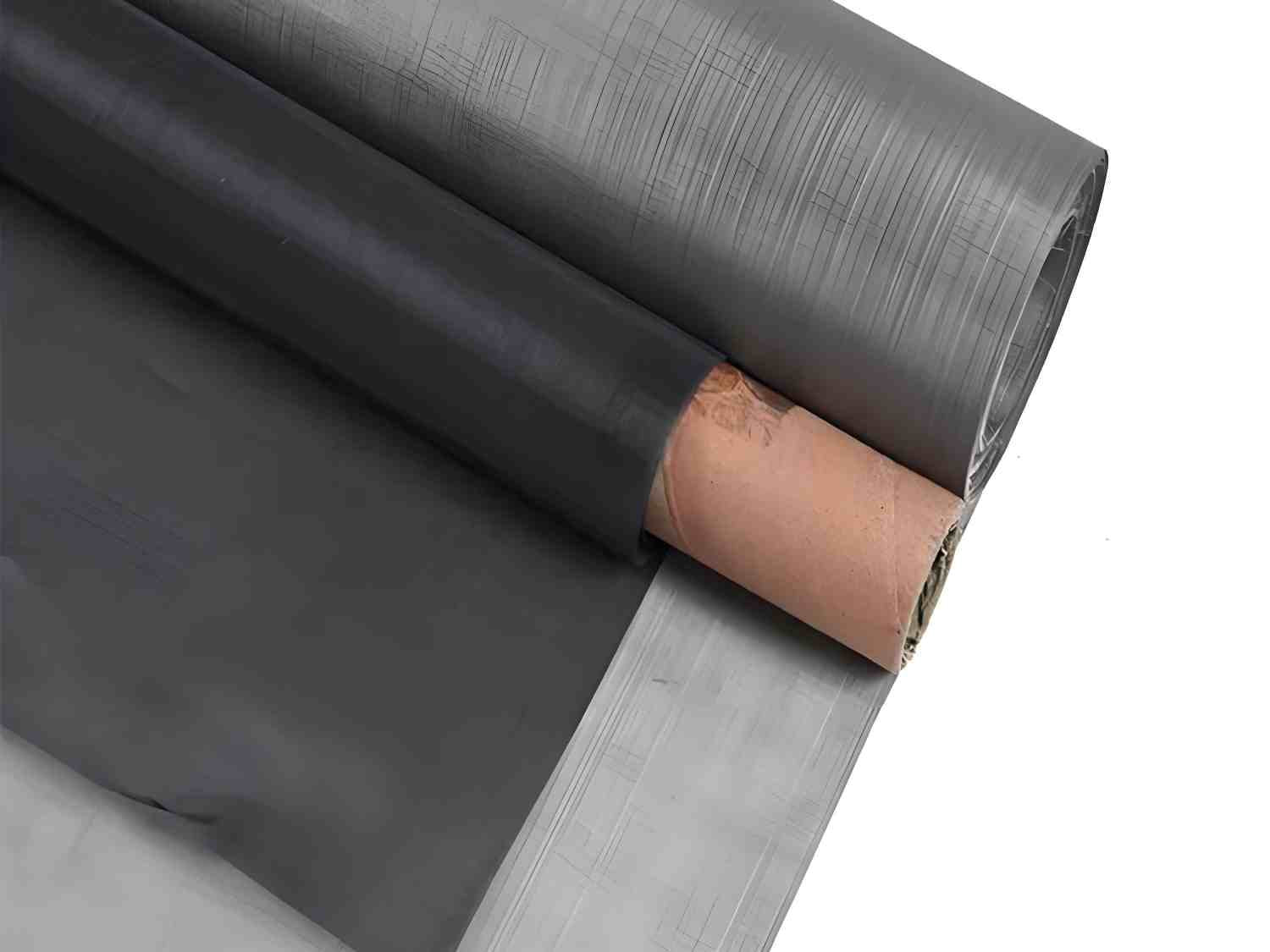

| Product name | Titanium Wire Mesh |

| Material | TA1 (Ti≥99.5%) |

| Mesh Size | 2 Mesh – 400Mesh (standard) |

| Wire Diameter | 0.04mm – 3.0mm (customizable) |

| Free simple | Sample is available |

| Packaging | Jumbo bag and pallet |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

Titanium wire mesh is a high-performance metal mesh product meticulously engineered by our company, crafted from premium titanium wires (with a purity of 99.0% or higher, or titanium alloys) using advanced weaving technologies. Renowned for its exceptional combination of corrosion resistance, high strength-to-weight ratio, biocompatibility, and heat resistance, titanium wire mesh stands as a cutting-edge solution for industries operating in extreme or specialized environments where conventional materials fall short.

Material Characteristics

- Exceptional Corrosion Resistance: Titanium forms a dense, protective oxide film on its surface, which self-heals even when damaged, providing unparalleled resistance to corrosion in harsh environments. It withstands attack from seawater, chlorine, nitric acid, sulfuric acid (under specific conditions), and many other aggressive chemicals. This makes titanium wire mesh ideal for marine, chemical processing, and desalination applications where corrosion is a critical concern.

- High Strength-to-Weight Ratio: Titanium boasts a strength comparable to many steels but with approximately 40% of the weight. This unique property makes titanium wire mesh lightweight yet robust, reducing structural loads in applications such as aerospace components, automotive parts, and architectural structures without compromising performance.

- Excellent Heat Resistance: Titanium retains its mechanical properties at elevated temperatures, withstanding continuous operating temperatures up to 600°C (for pure titanium) and even higher for titanium alloys. It resists oxidation and creep under heat, ensuring stability in high-temperature environments like industrial furnaces and gas turbines.

- Biocompatibility: Pure titanium is biocompatible, meaning it is non-toxic and does not trigger adverse reactions when in contact with living tissues. This characteristic makes titanium wire mesh suitable for medical applications, such as implantable devices, surgical instruments, and biomedical filtration systems.

Structural Characteristics

- Precision Weaving for Uniformity: Our titanium wire mesh is produced using state-of-the-art weaving techniques, ensuring consistent mesh size, uniform opening distribution, and precise filtration accuracy. The tightly interwoven titanium wires create a stable structure that maintains its shape under mechanical stress, pressure, or temperature fluctuations, guaranteeing reliable performance in critical applications.

- Enhanced Durability: The inherent strength and corrosion resistance of titanium, combined with the robust weaving pattern, 赋予 the mesh exceptional durability. It is resistant to wear, abrasion, and fatigue, ensuring a long service life even in high-demand environments.

- Smooth Surface and Low Fouling: The smooth surface of titanium wire mesh minimizes the adhesion of particles, sediments, and biological fouling. This reduces maintenance requirements, as the mesh can be easily cleaned with water, chemical solutions, or ultrasonic methods, maintaining optimal performance over time.

- Customizable Specifications: To meet diverse industrial needs, we offer extensive customization options for titanium wire mesh. This includes varying mesh counts (from fine meshes for microfiltration to coarse meshes for heavy-duty screening), wire diameters, mesh shapes (square, rectangular, etc.), and sheet sizes. Our technical team collaborates with customers to develop tailored solutions that align with their specific application requirements.

Applications

1. Chemical Processing

- Chlorine production anodes

- Acid regeneration plant filters

- Precious metal recovery screens

2. Marine & Offshore

- Desalination plant components

- Subsea ROV protective screens

- Ballast water treatment

3. Medical & Pharmaceutical

- Hydrogen generator electrode mesh

- Dental implant reinforcement

- Bioreactor filtration

4. Aerospace & Defense

- Composite reinforcement

- Satellite radiation shielding

- Jet engine acoustic liners