| Product name | Hastelloy Wire Mesh |

| Material | Hastelloy C276 (57-63% Cr, 15-17% Ni, 15-17% Mo) |

| Mesh Size | 2 Mesh – 2300Mesh (standard) |

| Wire Diameter | 0.03mm – 3.0mm (customizable) |

| Free simple | Sample is available |

| Packaging | Jumbo bag and pallet |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

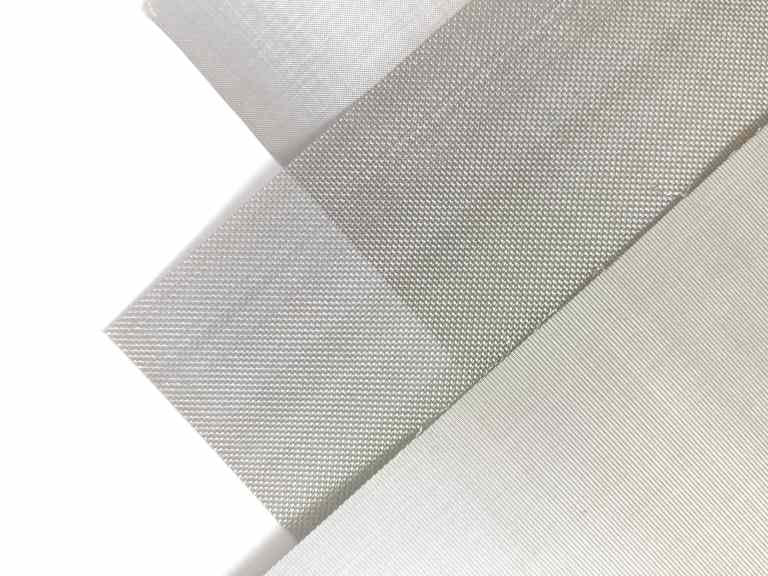

Hastelloy wire mesh is a premium-grade metal mesh product meticulously crafted by our company, utilizing high-quality Hastelloy alloy wires. Hastelloy is a family of nickel-based superalloys renowned for their exceptional resistance to corrosion, high-temperature strength, and durability in the most extreme industrial environments. Composed primarily of nickel, along with significant amounts of chromium, molybdenum, and other alloying elements (such as tungsten, iron, or cobalt, depending on the grade), Hastelloy wire mesh is engineered to perform reliably in applications where conventional metals and even other stainless steels fail.

Material Characteristics

- Unmatched Corrosion Resistance: Hastelloy alloys exhibit extraordinary resistance to a wide range of aggressive media, including strong acids (sulfuric acid, hydrochloric acid, nitric acid), alkalis, chlorides, and organic compounds. This resistance is attributed to their high nickel content, which provides a stable matrix, and the addition of molybdenum and chromium, which enhance resistance to pitting, crevice corrosion, and general corrosion. Even in highly concentrated or high-temperature corrosive environments, Hastelloy wire mesh maintains its integrity.

- Exceptional High-Temperature Performance: Hastelloy wire mesh retains its mechanical strength and corrosion resistance at elevated temperatures, withstanding continuous operating temperatures up to 1200°C (depending on the specific grade). It resists oxidation, carburization, and sulfidation at high temperatures, making it suitable for use in furnaces, chemical reactors, and exhaust systems exposed to extreme heat.

- Superior Mechanical Strength: The alloy composition of Hastelloy gives the wire mesh high tensile strength, creep resistance, and toughness, even at high temperatures. This allows it to withstand mechanical stress, pressure, and vibration in demanding applications without deformation or failure.

- Good Fabricability: Despite its high strength, Hastelloy wire can be woven into intricate mesh patterns with precise dimensions. It offers good ductility and weldability, enabling customization into various mesh sizes and shapes to meet specific application requirements.

Structural Characteristics

- Precision Weaving for Uniformity: Our Hastelloy wire mesh is produced using advanced weaving techniques, ensuring uniform mesh size, consistent opening distribution, and precise filtration accuracy. The tightly interwoven wires form a stable structure that maintains its shape and performance even under extreme corrosion, temperature, or mechanical stress.

- Enhanced Durability: The combination of superior corrosion resistance, high-temperature stability, and mechanical strength makes Hastelloy wire mesh exceptionally durable. It has a long service life in harsh environments, reducing the need for frequent replacement and lowering maintenance costs.

- Smooth Surface and Low Fouling: The surface of Hastelloy wire mesh is smooth, minimizing the adhesion of contaminants, particles, and corrosion by-products. This simplifies cleaning and maintenance, ensuring the mesh retains its filtration efficiency and performance over time.

- Customizable Specifications: To cater to diverse industrial needs, we offer extensive customization options for Hastelloy wire mesh. This includes varying mesh counts (from fine meshes for precision filtration to coarse meshes for heavy-duty applications), wire diameters, mesh shapes (square, rectangular, etc.), and sheet sizes. Our technical team collaborates with customers to develop tailored solutions that align with their specific application requirements.

Applications

1. Chemical Processing

- Acid regeneration plant filters

- PVC production chlorine gas scrubbers

- TiO₂ manufacturing chlorination reactors

2. Pollution Control

- FGD scrubber demister pads

- Waste incineration flue gas filters

- Stack gas quench systems

3. Oil & Gas

- Downhole screens in sour wells

- Subsea manifold protection

- Refinery acid alkylation units

4. Specialty Applications

- Nuclear fuel reprocessing

- Pharmaceutical CIP systems

- Marine exhaust scrubbers