| Product name | FeCrAl Wire Mesh |

| Material | 1Cr13Al4 (15-22% Cr, 4-7% Al,) |

| Mesh Size | 2 Mesh – 150 Mesh (standard) |

| Wire Diameter | 0.06mm – 3.0mm (customizable) |

| Free simple | Sample is available |

| Packaging | Jumbo bag and pallet |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

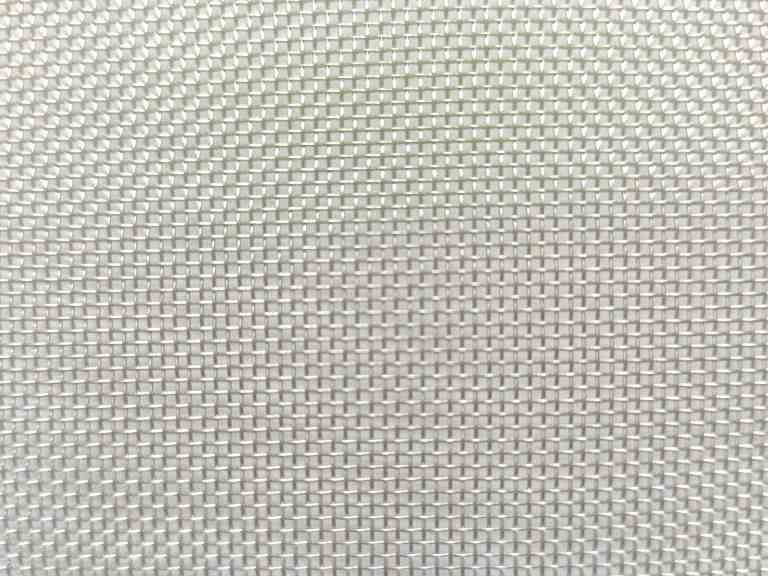

FeCrAl wire mesh, also known as iron-chromium-aluminum wire mesh, is a high-temperature resistant metal mesh product expertly manufactured by our company using premium FeCrAl alloy wires. Composed primarily of iron, chromium (15-30%), and aluminum (4-10%), with trace amounts of other elements like silicon and nickel, this alloy mesh is specifically engineered to excel in extreme high-temperature environments. Its unique composition grants it exceptional oxidation resistance, high-temperature strength, and long service life under thermal stress, making it an indispensable solution for industries requiring reliable performance in intense heat.

Material Characteristics

- Outstanding High-Temperature Resistance: FeCrAl alloy forms a dense and stable aluminum oxide (Al₂O₃) film on its surface when exposed to high temperatures. This protective film prevents further oxidation and scaling, allowing the wire mesh to withstand continuous operating temperatures up to 1200°C and short-term exposure to temperatures as high as 1400°C. This makes it far more heat-resistant than stainless steel meshes, which typically max out at 800-1000°C.

- Excellent Oxidation and Corrosion Resistance: The chromium and aluminum content in FeCrAl alloy enhances its resistance to oxidation and corrosion in high-temperature environments, including in air, combustion gases, and certain industrial atmospheres. It resists degradation from sulfur-containing gases and other corrosive agents commonly found in furnaces and industrial processes.

- High Mechanical Strength at Elevated Temperatures: FeCrAl wire mesh retains good tensile strength and structural stability even at high temperatures, minimizing deformation or sagging under thermal stress. This strength ensures consistent performance in applications involving prolonged heat exposure, such as furnace components and heat treatment equipment.

- Low Electrical Resistance and High Heating Efficiency: FeCrAl alloy has a relatively high electrical resistance compared to pure metals, making it suitable for use as heating elements. When used in heating applications, the mesh heats up quickly and evenly, providing efficient thermal output—an advantage in industrial heating systems and electric furnaces.

Structural Characteristics

- Uniform and Stable Mesh Construction: Our FeCrAl wire mesh is produced using precision weaving techniques, ensuring uniform mesh size, consistent opening distribution, and reliable performance under high temperatures. The tightly interwoven wires form a robust structure that maintains its shape and integrity even after repeated thermal cycling, ensuring long-term functionality.

- Heat-Shock Resistance: The mesh is designed to withstand rapid temperature changes (thermal shock) without cracking or breaking. This property is critical for applications where heating and cooling cycles are frequent, such as in industrial ovens and heat treatment processes.

- Durable and Long-Lasting: The combination of high-temperature resistance, oxidation resistance, and mechanical strength gives FeCrAl wire mesh an exceptionally long service life in harsh thermal environments. It outperforms many other metal meshes in terms of durability, reducing the need for frequent replacement and lowering maintenance costs.

- Customizable Specifications: To meet diverse industrial needs, we offer extensive customization options for FeCrAl wire mesh. This includes varying mesh counts (from coarse meshes for heavy-duty applications to finer meshes for filtration), wire diameters, mesh shapes (square, rectangular), and sheet sizes. Our technical team collaborates with customers to tailor the mesh to their specific high-temperature application requirements.

Applications

1. Heating Technology

- Electric resistance heating elements

- Industrial furnace components

- Thermal processing equipment

2. Filtration Systems

- Molten metal filters

- High-temperature gas filtration

- Waste incineration filters

3. Energy Sector

- Fuel cell components

- Burner protection screens

- Catalyst support grids

4. Specialty Applications

- Aerospace heat shields

- Nuclear reactor components

- Semiconductor processing fixtures